From idea to series production – Your partner for innovative manufacturing solutions

At Thoptec, you get all manufacturing services from a single source. From the initial design idea to prototype construction and series production – we accompany you through the entire development process.

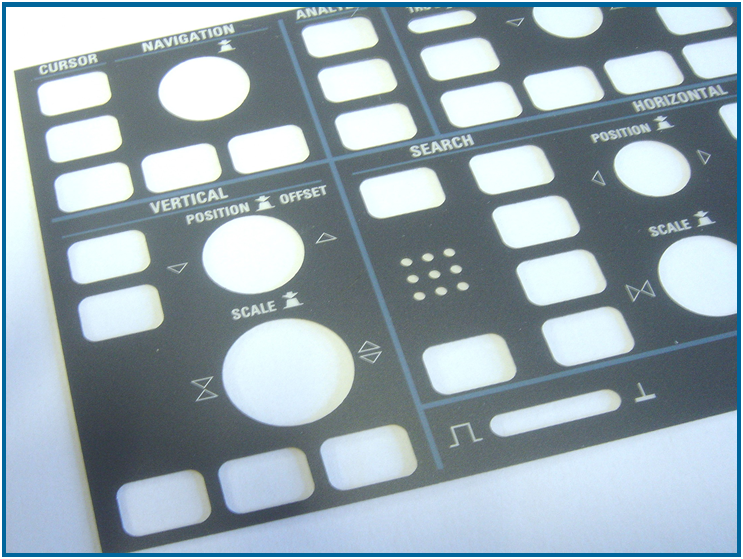

Injection Molding & Plastic Injection Molded Parts

Manufacturing according to your wishes

We have injection molding machines for small parts as well as larger machines with a clamping force of up to 100 tons. Through our own design office, we support you already in the development and design of your specific injection molded parts.

Thus, we are able to manufacture high-quality injection molded parts according to your requirements – regarding intended use, material properties, as well as surface and color.

Advantages of our small injection molding machines:

- Tool holder takes over master mold function

- Reduced tool size = significantly lower costs

- Low energy consumption

- Closed cooling system = resource-saving production

- Lower unit prices through optimized processes

Design & Development

Modern CAD technology for your ideas

We have a design office with state-of-the-art CAD hardware and software. Inquiries for the development and design of plastic injection molded parts are always welcome.

Our service:

- Complete product development from the initial idea

- Tool design by experienced specialists

- Partnership with high-performing toolmakers

- Fast quotation for your project

We usually take over the design of the tools and have them manufactured by our proven partner companies. This way, you receive optimal quality at controlled costs.

Rapid Prototyping and Small Series

3D Printing

In 3D printing, three-dimensional workpieces are built up layer by layer under computer control. The construction is done from liquid or solid materials according to specified dimensions and shapes, taking into account corresponding shrinkage.

The production of parts using 3D printing is becoming increasingly important, especially for small quantities as a more cost-effective alternative to expensive tool procurement and for the prototype area.

Our 3D printing materials:

- TPE / TPU

- PA6.6

- ABS

- Other plastics depending on requirements

Advantages:

- Cost-effective alternative for small quantities

- Fast prototype creation

- Constantly increasing quality through new filaments

- Complex geometries

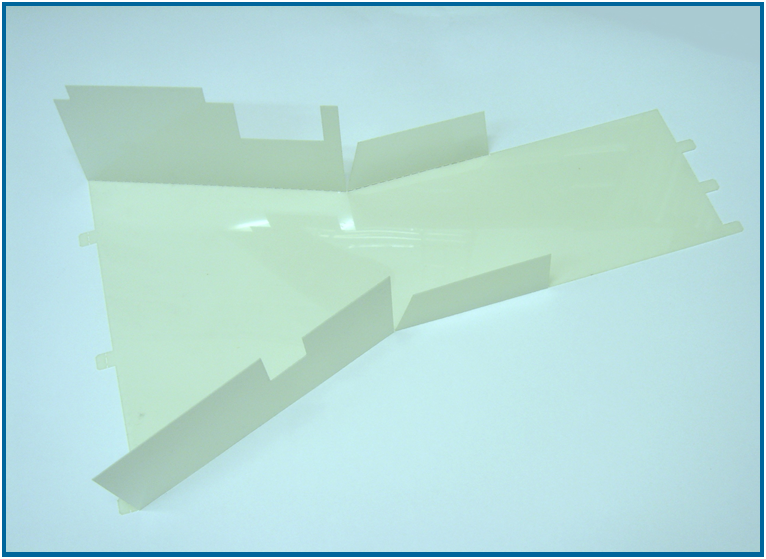

Vacuum Casting

Vacuum casting is an efficient process for producing high-quality plastic parts in small quantities in the shortest possible time – ideal for testing, presentations, or pre-production.

The basis is a master model (e.g., from 3D printing), from which a flexible silicone mold is created. This mold can be used to produce detailed copies from castable plastics under vacuum conditions.

Our materials:

- Special vacuum casting resins

- Other materials upon request

Advantages:

- Fast implementation – prototypes and small series within a short time

- A wide range of materials – from elastic to rigid, from light to dark

-

Near-production quality – appearance and feel match industrial end products

- Complex geometries